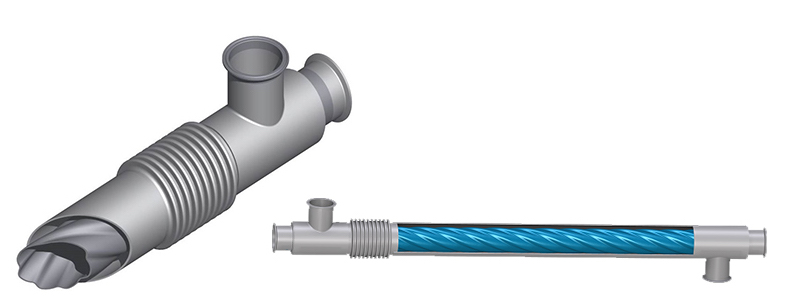

Ultra-Corrugated Double-Tube Heat Exchangers

The most basic type of tubular heat exchanger consisting of a tube within a tube.

The double tube design is the most basic type of tubular heat exchanger consisting of a tube within a tube. The tube diameter (up to 4”) makes it ideal for processing viscous products which may or may not contain particulates.

Application

Double tube heat exchangers are ideal for particulate processing, direct regeneration heat recovery, or where the use of a product pig for minimized loss is required.